Effluent Reduction

We would love to help your site towards zero discharge. On the way we would seek to reduce disposal costs, improve product yield and ensure there is improvement in environmental impact.

Summary of activities:

Membrane Plants

Contact us to discuss your particular application

Engineering Services

EPI's effluent reduction capabilities can be covered in two broad categories:

a) Process Engineering.

This covers a myriad of activities from site audits through process design and on to turnkey project management.

b) Membrane Processing.

Where applicable, EPI can design, build, install and commission turnkey membrane processing equipment.

By way of hypothetical example, a full involvement at a given site would cover areas such as:-

Site Audit:

- Audit existing process engineering and management to identify main areas of yield loss, out of specification product and effluent sources.

- Audit existing water usage patterns, again to identify major sources of usage, wastage and losses. (Water usage reduction basically equals effluent volume reduction).

Audit Report:

Collation of the audit findings to highlight opportunities for:

- Effluent reduction

- Product yield enhancement

- Product recovery / re-use

- Adding value to current waste streams

- Water re-use / recycling

Budget Costings:

Typically, a review of the audit will highlight several major opportunities for effluent reduction and/or product recovery.These are "broad-brush" costed in order to identify specific projects that are attractive for economic and/or strategic reasons.

Project Proposals:

Any favoured strategies can then be formally designed and costed with a view to proceeding if the budget analysis is confirmed.

Project Implementation:

Project implementation is tailored to best suit the customer's need, be it turnkey contracts or daily rate payments. All aspects of the project can be handled by Environment Products International Limited, including process design, equipment supply, pipework installation, automation, electrical installation, project management, commissioning, cost control and operator training.

Caustic Recovery, Acid Recovery

In recent years EPI has installed several very successful chemical recovery and chemical re-use systems, both in new plants and retrofitting existing operations. Obvious benefits are chemical savings, effluent TDS reduction and effluent pH control. Depending on the application 80-90% of the chemical solution can be recovered for re-use. This applies to both the caustic and acid streams. By applying this percentage to your own chemical and effluent figures, you will get an idea of the savings to be had. Customised solutions can include clarification and NF or UF membrane treatment. Ideal applications are “use and dump” systems, such as evaporator CIP.

Condensate recovery

Evaporator condensate is an excellent source of re-use water. In the Dairy Industry, the water removed during the evaporation of milk can be captured. This water is mainly of good quality, with low TDS and low solids. However, it does contain organic contaminants, odour and BOD. These contaminants combine to make the condensate unsuitable for use in all but the lowest grade applications. However, if the condensate is processed through a special reverse osmosis (RO) plant, the quality can be improved markedly. A simple post treatment can then make the “polished” water suitable for widespread re-use.

Brine Recovery

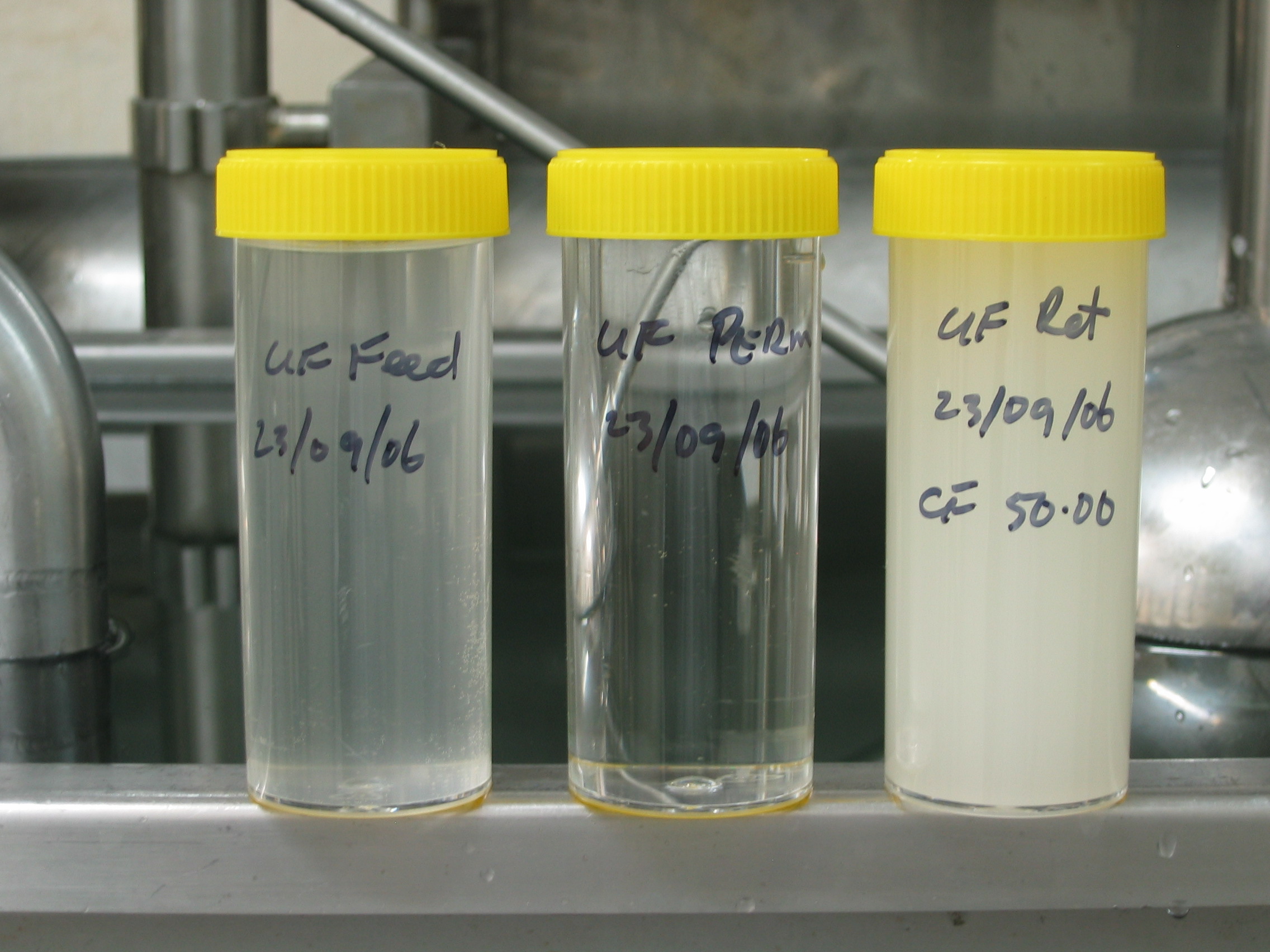

Brines used in cheese manufacture, meat processing and vegetable processing are quickly dirtied by proteins, bacteria and other contaminants. Untreated, these streams need to be dumped regularly with a resultant heavy TDS (sodium, chloride) effluent loading. Microfiltration (MF), Ultrafiltration (UF) or Nanofiltration (NF) membranes will freely allow Na and Cl passage, whilst preventing the passage of contaminants. Hence, using membrane processing it is possible to continuously clean up the brine and simultaneously reduce effluent and improve product quality.

Water From Effluent

Both municipal and industrial effluents are now valid sources of re-use water. Some of the streams suitable to recover water from include: “end-of-pipe” cheese factory effluent; municipal effluent (sewer mining); MBR treated wastewater; secondary effluent (ex conventional wastewater treatment); DAF, IAF, Jetflote treated wastewater.

TDS Reduction, N Reduction

Many effluent streams are not able to be used for irrigation or other re-use options solely due to one particular component being above critical limits. The selective nature of membrane processing means that UF, NF or RO can be used to reduce component levels in order to meet specification.

Salty Whey Recovery

Salty whey is a high salt byproduct of cheesemaking. This stream still contains valuable protein and lactose. Using NF membranes it is possible to both recover the protein and lactose and simultaneously dramatically reduce the COD of the effluent stream.